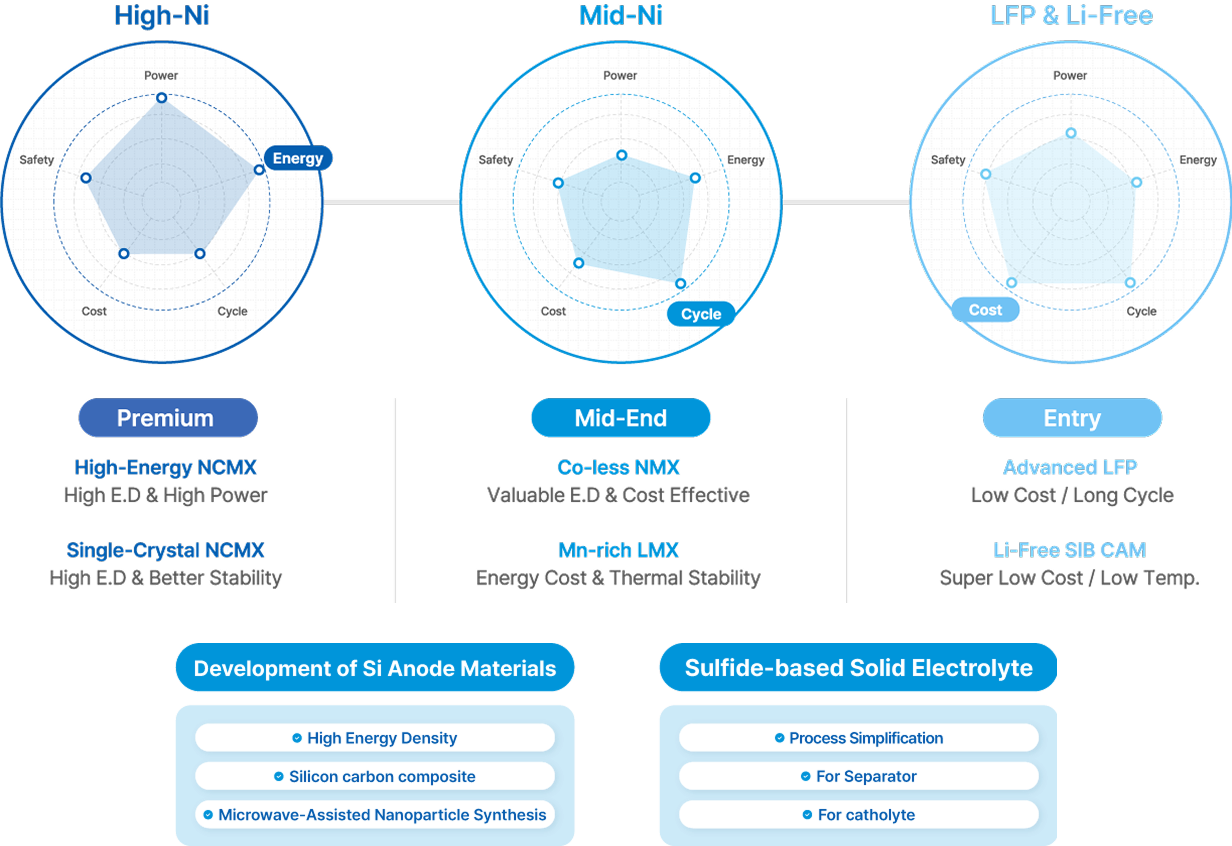

Research Direction

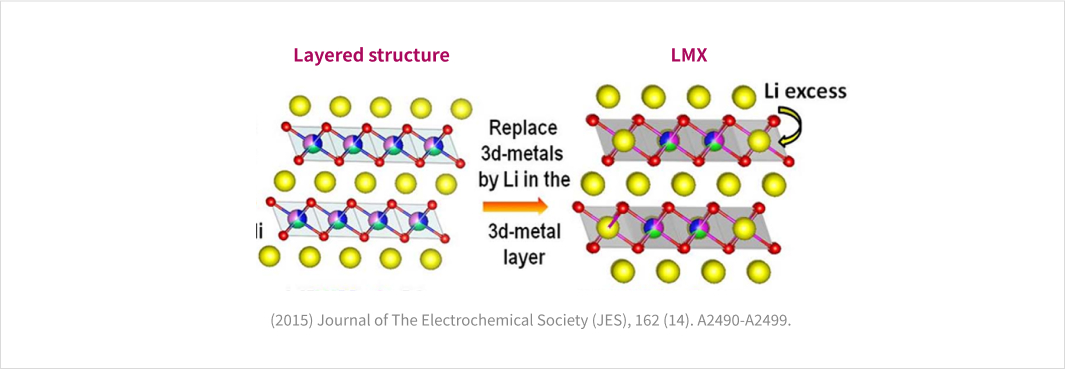

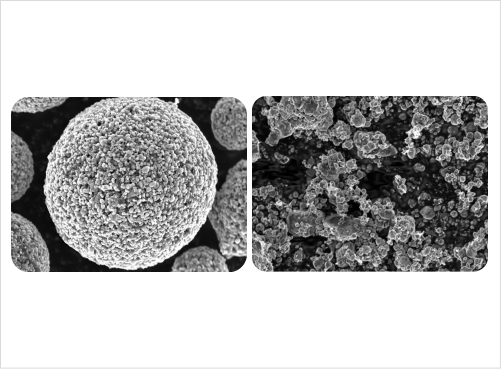

Ecopro BM is focusing on the development of high-Ni cathode materials based on innovative technology and independent manufacturing technology, and its main products are high-capacity and high-performance cathode materials with Ni content of over 90%. In order to overcome the degradation (cracks, gas, reduced lifespan, etc.) that occurs as the Ni content increases, we are maximizing material performance and improving stability through various research and experiments. As one of the solutions to the cause of degradation, we have succeeded in mass producing single crystal technology, which is a single particle rather than polycrystalline, for the first time in the world. Ecopro BM is doing its best to provide valuable products to customers through continuous research and innovation, and to realize customer satisfaction through customized product development.

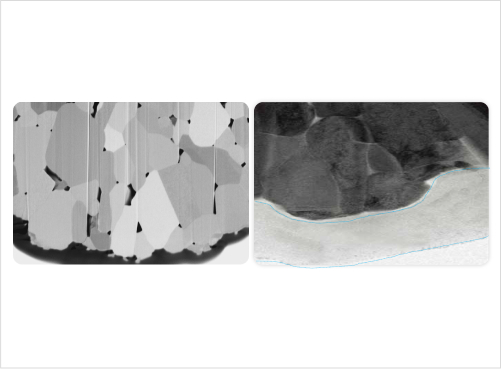

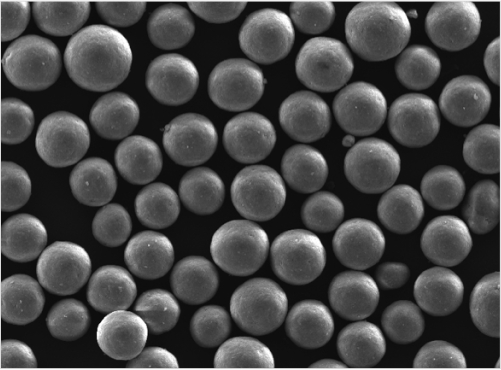

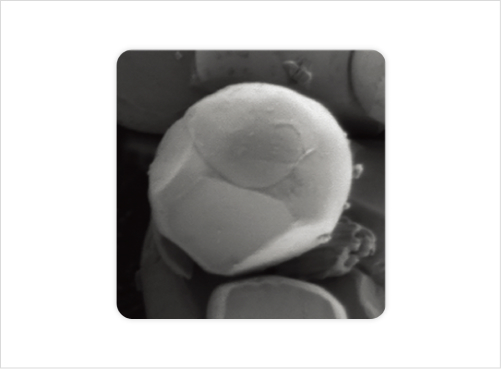

Single Crystal

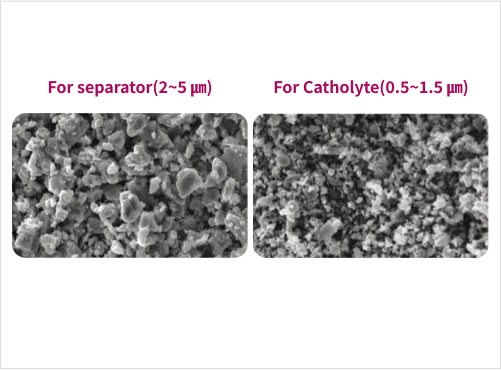

Coating / Doping technology